Description

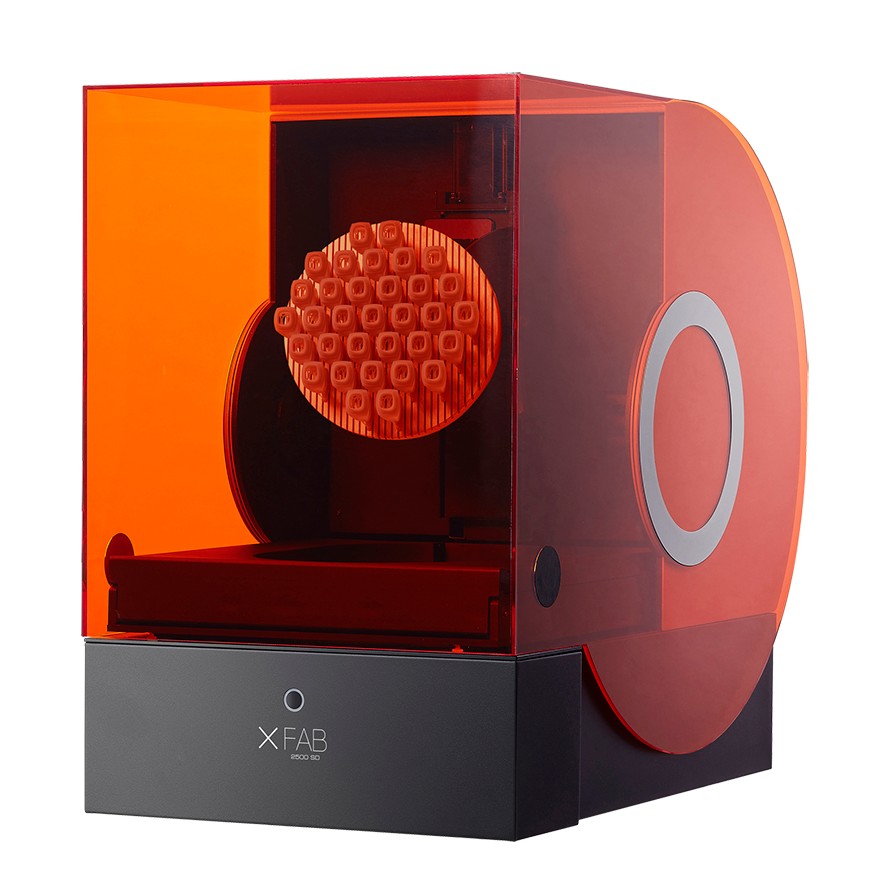

XFAB® is the innovative desktop 3D printer equipped with the same technology used in our professional printers. XFAB® is perfect for industrial design prototyping, digital dental modelling, and artisanal jewellery making, as well as in educational settings and makerspaces.

The best resolution on the market is now accessible to everyone:

Cylindrical printing area 180 mm in diameter, with 20% greater printing volume compared with other 3D printers on the market

Compact design for professional desktop use

12 types of material available for industrial applications, jewellery, dental applications, and educational/makerspaces (riportare link alle relative sezioni)

USB plug and play

XFAB® uses a wide range of 3D printing materials formulated specifically for industrial applications, jewellery, prototyping, and the dental sector. These include acrylic resins; ABS-like and polypropylene-like materials; transparent, flexible and rubber-like materials; biocompatible, nanoceramic, and wax-like materials. These materials are all designed, developed, and produced in-house at DWS, to guarantee the quality of the finished product and optimal physical-mechanical performance.

The material smart cartridges for the XFAB® 3D printer have been designed to ensure that resin refills are simple, fast, and safe. Thanks to these smart cartridges and the compression mechanism inside the XFAB®, no manual intervention is required and the risk of accidental spills is eliminated.

Specs

- 3D Printing Method: Laser Stereolithography

- Working Area: Ø 180×180 mm

- Laser Source: Solid State BluEdge® BE-1300X

- Slice Thickness* 10-100 microns

- Scanning Method: Galvanometer

- Software: Fictor® XFAB® edition, Nauta® XFAB® edition

- Input File Format: .stl, .slc, .nauta, .fictor, .mkr, .3dm,

- .3ds, .ply, .obj, .lwo, .x

- Machine Size: 400x606x642 mm

- Operating Temperature and Humidity: 20°-25°C / 60%

- Power Supply: 24V DC with AC 240/100V / 50-60 Hz external supplier included

- Operating System: Windows7 or higher

- Memory: 2 Gbyte

- Graphics Card: compatible with OpenGL

- I/O Interfaces: 1 USB port

- Connectivity: 1 active internet connection

- Recommended Configuration: Dual Core Processor or above, memory 4 GB