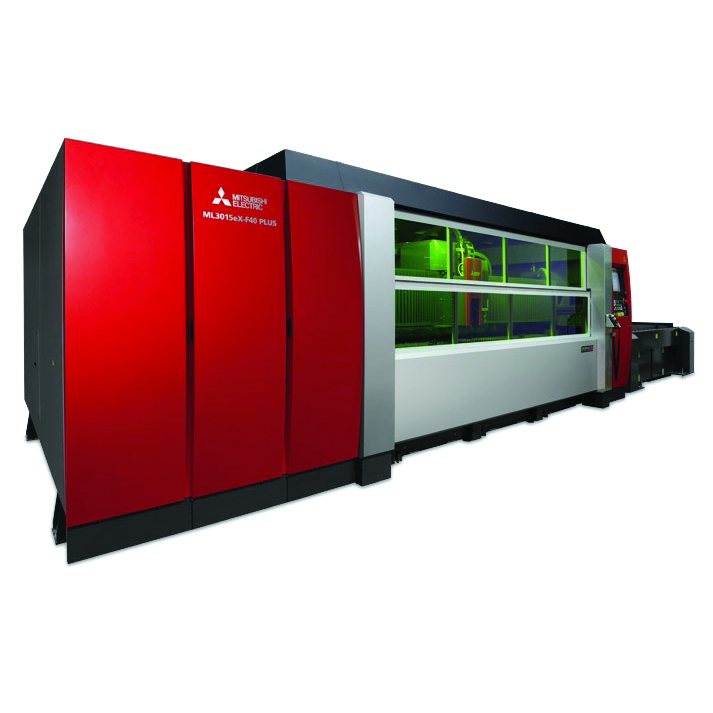

Description

| Model | 3015eX-F |

|---|---|

| Machine structure | X/Y – Precision Rack & Pinion – Z=Precision Ball Screw |

| Travel drive method | X-Y-Z simultaneous 3 axes (Z axis height control is also possible) |

| Max. workpiece size (inch) | 120.1 x 60.0 (3050mm x 1525mm) |

| Table pass height | 34.6 (879mm) |

| Processing access | Powered Manual Door |

| Pallet changer | Provided (Automation Ready) |

| X-axis stroke (inch) | 122 (3,100 mm) |

| Y-axis stroke (inch) | 61 (1,565 mm) |

| Z-axis stroke (inch) | 5.9 (150 mm) |

| Rapid travel speed (X, Y) (inch / min) | 3940 (single axis), 5550 (simultaneous) |

| Max. processing feedrate (inch / min) | 3937 IPM (50 m/min) |

| Positioning precision (inch) | .0019/20 (0.05/508mm) |

| Drive motor type | Intelligent AC Servo |

| Max. workpiece weight (lb) | 2050 (930 kg) |

| Machine unit dimensions (W x H x D) (inch) | 408.3 x 88.6 x 116.2 |

| Machine system weight (lb) | 28090 (12741kg) |