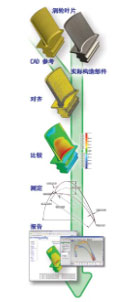

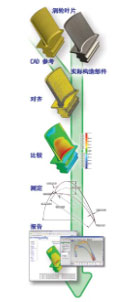

Digitally inspect as-built versus as-designed parts

You design in 3D, so why not inspect in 3D? Geomagic Qualify enables fast, accurate, easy-to-understand graphical comparisons between CAD models and as-built parts for first-article inspection, inline or shop-floor inspection, trend analysis, and in-depth assessment.

Inspect products in a fraction of the time

With Geomagic Qualify, inspection and approval can be completed in hours instead of weeks accelerating time to market, significantly reducing cost and giving you a measurable competitive advantage in the design/manufacturing process.

Get accurate, certified results

Geomagic Qualify bases inspection on surfaces defined by tens of thousands of points, rather than the five or ten points that previously defined a CMM surface. PTB certifies that Geomagic Qualify’s fitting results are accurate to less than 0.1 micrometers in length and 0.1 arcseconds (1/36,000 of a degree) in angle compared to the official reference value.

Improve design efficiency

An intuitive user interface guides you through the entire align, compare, evaluate and report workflow. Graphical comparisons of “as designed” vs. “as manufactured” information aids the designer’s understanding of problems, enabling quicker turnaround time for design changes.

Sustain manufacturing quality in real time

Maintain quality control for in-line production and shop-floor inspection. Trend analysis enables statistical process control (SPC) on multiple samples, providing insights into deviation trends. Deviation color maps allow uses to instantly identify problem areas that can be further analyzed – now or later.

Perform in-depth product and process assessment

Take advantage of Geomagic Qualify’s sophisticated analysis features including wall thickness, gap and flush (G&F), edge comparison, geometric dimensioning & tolerancing (GD&T), as well as 2D and 3D dimensioning. Quickly assess out-of-tolerance conditions to enable immediate correction to the manufacturing process.

Collaborate on the inspection process

Generate detailed reports with numeric inspection data, multiple views, annotated user-defined views, notes and conclusions. Use Geomagic Review to share inspection results online with engineers, suppliers, partners, contractors and customers at other physical locations.