Description

Standard version:

– Movable arm in 2 positions with weight compensation.

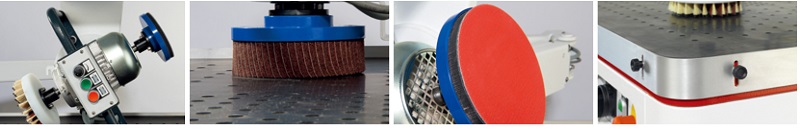

– Deburring disc for the removal of rough burrs.

– High friction mat for small parts.

– The grinding dust is collected in a removable tray.

– Frequency-controlled drive.

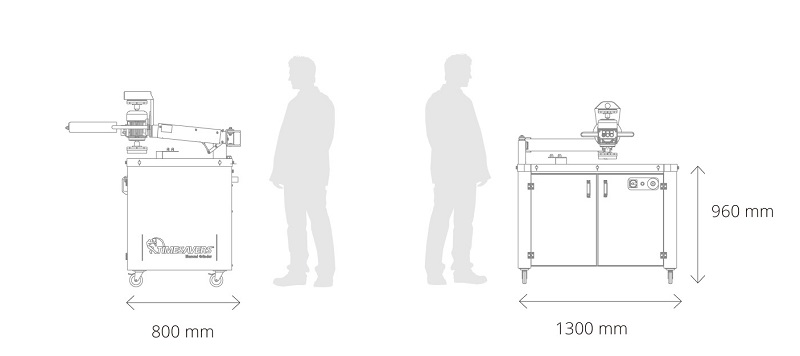

– 1300 x 800 mm bench.

– Weight approx. 270 kg.

– 400 V connection with vacuum table.

– 1.5 kW main motor.

– Side panels that can be adjusted with regard to height for personal protection and machining large parts.

– CE certified.

Applications and benefits:

– Long service-life flap brushes and therefore a reduction in material costs.

– 3 – 4 times faster than manual deburring.

– Uniform edge rounding/deburring.

– Affordable starting model.

– Optimum user friendliness.