Description

| ||

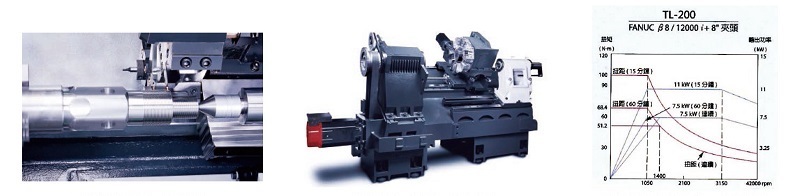

| 电脑数控车床内部构造 | 电脑数控车床的床身外观 | 电脑数控主轴功率 扭矩输入状态变化图表 |

| 产品特点 | ||

| 一、强大的功能:斜床排屑+ 多重保护结构+ 自动润滑+ 智能节能模式 | ||

| ♦倾斜角度达30°斜床结构使操作人员上下工件更轻松且排屑顺畅。 ♦采用以工业级橡胶一体刮刷片+ 不锈钢滑轨覆盖双重保护,保证车床经久耐用。 ♦将车削铁屑与冷却液隔离在机床内,使加工场地始终保持干净整洁。 ♦配备导轨、丝杆自动润滑系统,保证机床重要零部件随时得到润滑、随时保持机床良好状态。 ♦自动润滑系统在待机时智能开关机,避免浪费节约宝贵资源。 | ||

| 二、机身超强度结构 | ||

| ♦采用了低重心机身及30°正斜床设计,为机头、刀塔及尾座提供了极为稳固的基座。 ♦床台采用一体铸造成型+ 加强肋构造,采用高张力的米汉纳铸铁材料,运用热流平衡设计,能满足常年加工使用需求,先进的构造、科学的设计充分保证整体机床各方面工艺性能的卓异远超一般产品。 ♦ 机械强度对比传统机台增加20% 以上。可用于重切削并保持长期超高精度,而机台高刚性结构就能延长加刀具之使用寿命。 ♦滚珠导螺杆经过高频淬火处理及精密研磨,达到C3 最高研磨精度等级,确保最高的精度与耐用性。 ♦X、Z 轴均采用高性能线性滑轨,具备高精度、快速移动、低磨耗的特性,丝杆最快速度达到30m/min。 | ||

| 三、刀塔部分采用先进技术研发而成 | ||

| ♦采用伺服马达刀盘换刀定位技术,实现相邻刀具换刀时间仅需0.2秒、对面换刀时间为0.5 秒(业内先进水平) 。 ♦采用了超高精度离合器定位刀盘,保证机床在任何切削情形下刀塔刚性始终如一。 ♦采用先进技术的离合器具有自动对心、自动清洁与齿面结合面积大等特征。 | ||

| 四、超强切削能力 | ||

| ♦采用伺服马达刀盘换刀定位技术,实现相邻刀具换刀时间仅需0.2秒、对面换刀时间为0.5 秒(业内先进水平) 。 ♦采用了超高精度离合器定位刀盘,保证机床在任何切削情形下刀塔刚性始终如一。 ♦采用先进技术的离合器具有自动对心、自动清洁与齿面结合面积大等特征。 | ||

| 五、采用FANUC 0i-TF 操作系统 | ||

| ♦高加工性能、高运转率、便于使用、为企业带来最大化的效益。 ♦拥有强大的控制功能和先进的数字伺服技术实现高速高质量加工。 ♦先进的硬件技术、体积小、配线少、可靠性高、CNC 功能丰富且便于使用。 ♦Fanuc 一贯的操作界面优异的操作性能、功能按钮区分明确、可实现在线监控机床状态。 ♦丰富的用户自定义功能、简便的启动调试、强大的软件工具支持、易于维护。 | ||

| ||