Products

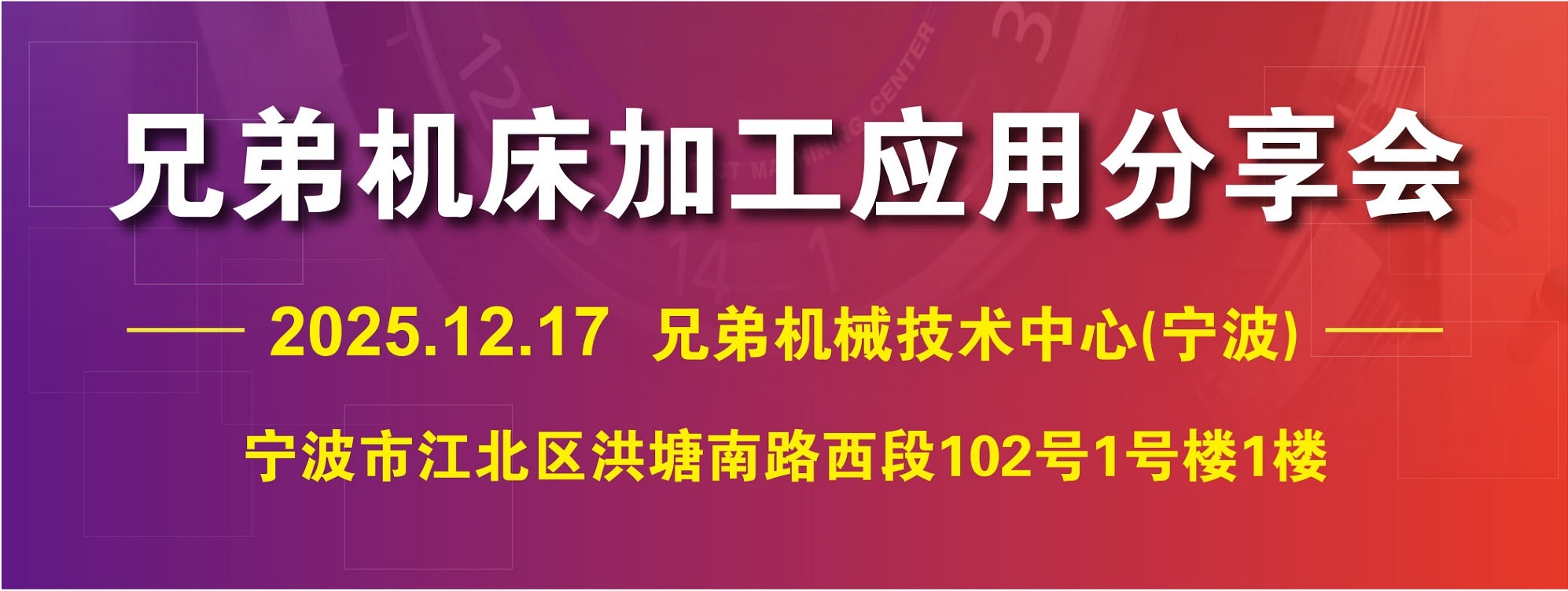

News & Events

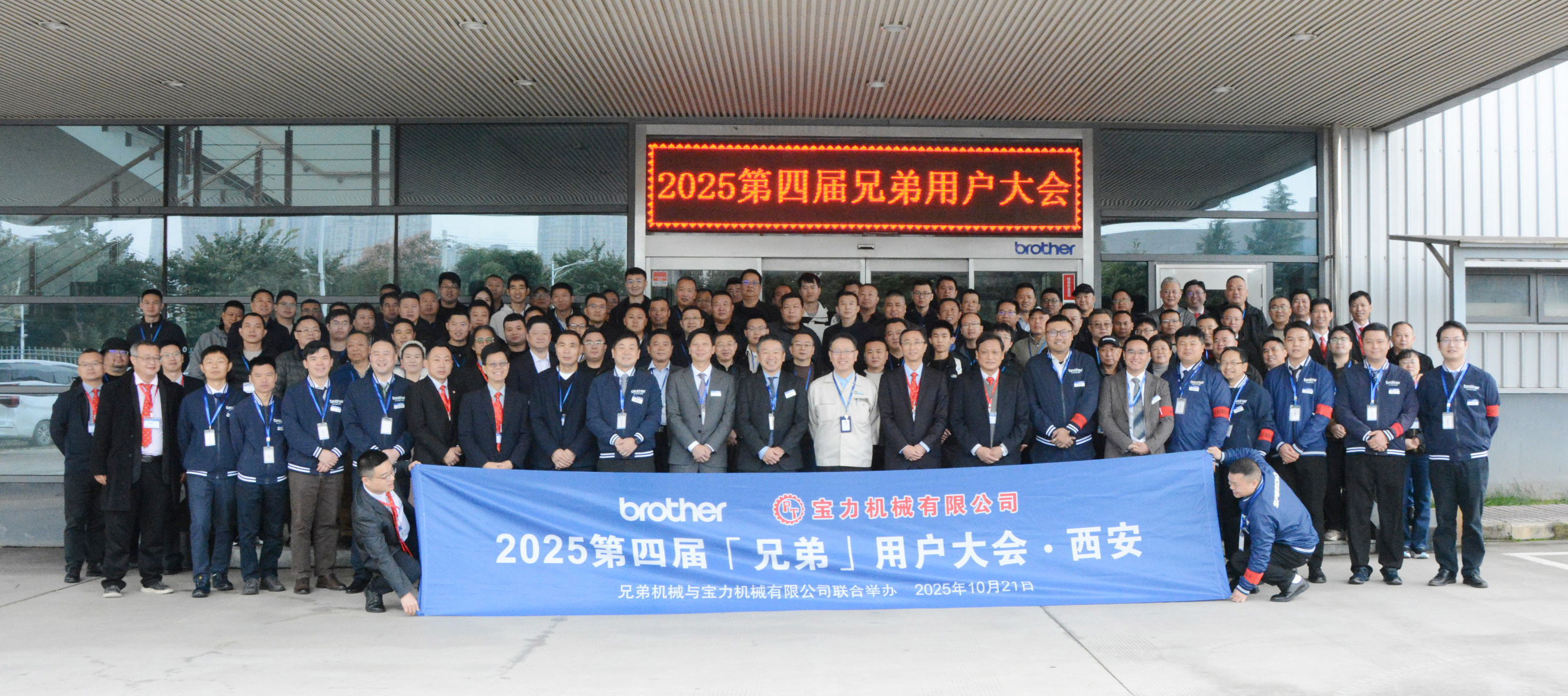

「Pro-Technic Machinery Group」

Founded in 1977, Pro-Technic Machinery Group has served the industrial sectors of mainland China and Hong Kong for over 45 years. The group has introduced fine machinery and advanced technology from around the world, providing high-quality pre-sales and after-sales services, is now a major machinery agent and integrated equipment manufacturer in China. With offices in 31 major industrial cities and special regions across China, including the Guangzhou Free Trade Zone, the group has a total of 32 locations. Pro-Technic Machinery Group has a team of 500 experienced pre-sales and after-sales staff providing prompt and professional services, offering specialized production solutions to customers.

The vision of Pro-Technic Machinery Group is "to become the best professional service provider in China for machinery field." The group is committed to advancing towards 'intelligent' manufacturing, continuously introducing high-end technologies from various regions, maintaining long-term and good cooperative relationships with many internationally renowned production equipment brands, assisting the industrial development of both mainland China and Hong Kong, working hand in hand with customers to create brilliance together.

Solution Centre

Solution Centre Service Hotline 400-889-8282

Service Hotline 400-889-8282