| Model | 3015 SR |

|---|---|

| Machine Travels: X x Y x Z in (mm) | 122 x 61 x 5.9 (3100 x 1550 x 150) |

| Workpiece Dimensions: W x D in (mm) | 120.1 x 60.0 (3050 x 1525) |

| Available Resonators: (model number/wattage output) | 32XP / 2700 |

| Motion Drive System Design | Helical Rack & Pinion |

| Processing Lens Focal Distance: in (mm) | 5.0/7.5/10.0 (127/190.5/254) |

| No. of control axes | 3 |

| Machine Structure | X-Y Helical Rack & Pinion, Z Precision Ball Screw |

| Travel Drive Method | X-Y-Z Simultaneous 3-axes (Z-axis height control is also possible) |

| Table Pass Height: in (mm) | 34.6 (880) |

| Processing Access | Power Operated Door |

| Pallet Changer | Provided |

| Rapid travel speed [X,Y]: in/min. (m/min.) | 3940 (100) single axis, 5550 (141) simultaneous |

| Max. processing feedrate: in/min. (m/min.) | 1970 (50) |

| Positioning Precision: in (mm) | 0.0019/20 (0.05/500) X, Y axis, 0.0039/4 (0.1/100) Z-axis |

| Repeatable accuracy [X,Y]: in (mm) | +/-0.00039 (+/-0.01) |

| Drive Motor Type | Intelligent AC Servo |

| Max. workpiece weight: lb (kg) | 1540 (700) |

| Installation Dimensions (W x D): in (mm) | 540.0 x 347.0 (13,846 x 8,812) |

| Machine Unit Dimensions (W x D x H): in (mm) | 404.5 x 116.3 x 93.7 (6,413 x 2,955 x 2,380) |

| Machine System Weight: lb (kg) | 28,090 (12,740) |

| Floor Space Req. sq. ft. (m2) | 1301 (121) |

| Type | Self contained PC NC |

| CPU | 64-bit |

| Display screen | 15″ TFT color LCD touch screen |

| Hard disk | 20.0 GB |

| Generator output control | Output Power, Frequency, Duty |

| Generator operation control | Beam ON/OFF, laser gas change, etc. |

| Drive system | X,Y,Z simultaneous control |

| Position detection system | Encoder |

| Min. command unit: in (mm) | 0.0001 (0.001) |

| Program input system | USB, Computer Link, Eternet LAN |

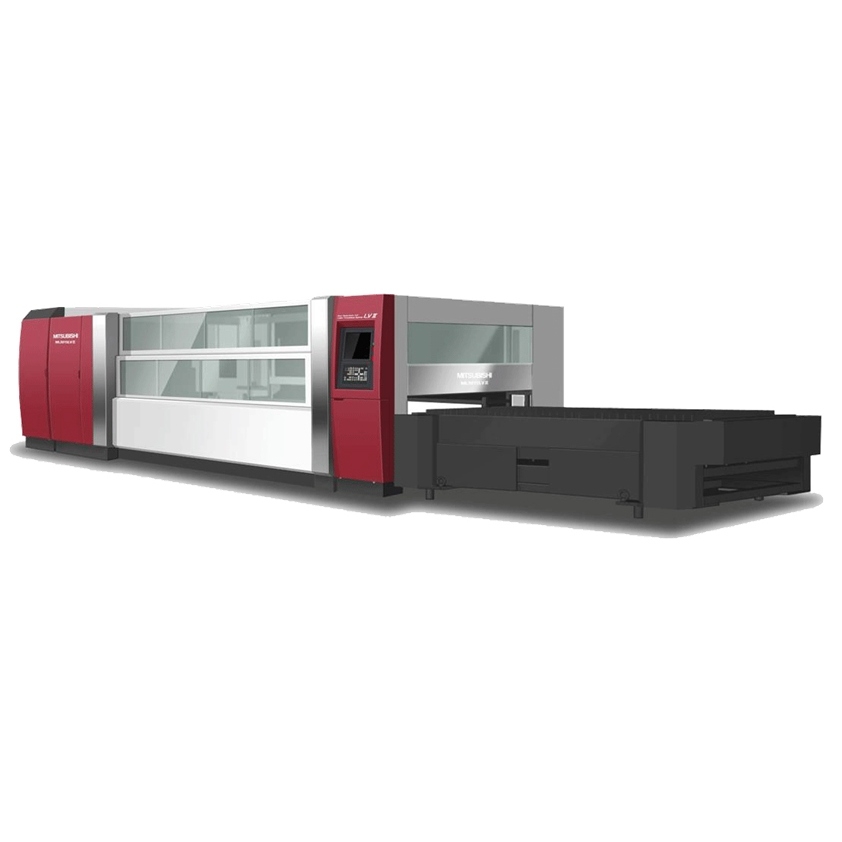

MITSUBISHI 2D Laser Cutting Machine

MITSUBISHI ML3015SR-32XP

SR SERIES

Higher-quality cutting, improved productivity and increased surface finish are just a few of the impressive features unique to the new SR laser. Innovative additions—including the PHXS Head with a lens cartridge design that facilitates constant centering, plus a faster graphical interface— lead to faster cutting and lower cost per part.

Other features allow for aggressive mild steel piercing, expanded options for programming and exceptional control in cutting, contributing to increased energy savings. Overall improvements unique to the SR include a 40 percent speed gain in thick-plate cutting, thanks to the improved resonator; and an up to 80 percent improvement in surface-finish quality for stainless steel cutting.

Back to Product Index

Back to Product Index

Solution Centre

Solution Centre Service Hotline 400-889-8282

Service Hotline 400-889-8282