News

As time flows swiftly, 2025 is drawing to a close. Looking back, Pro-Technic Machinery Group has left solid and meaningful footprints along a year marked by technical exchange, industry engagement, and team growth. From spring to winter, from domestic markets to the international stage, every event reflected our unwavering commitment to precision manufacturing and technological innovation. As we look ahead to the new year, we move forward with confidence and anticipation, firmly pursuing higher standards of quality and sustainable development.

31 Dec

Happy New Year 2026!

Pro-Technic Machinery Group wishes everyone a Happy New Year 2026!

31 Dec

2026 New Year Holiday Notice

In accordance with the national public holiday arrangements and taking into consideration our company’s operational needs, the 2026 New Year’s Day holiday schedule of Pro-Technic Machinery Group is as follows:

January 1, 2026 (Thursday): Holiday (one day)

January 2, 2026 (Friday): Normal business operations resume

We would like to take this opportunity to express our sincere appreciation for your continued support and trust over the past year.

Wishing you a Happy New Year 2026, good health, and continued success in your business!

On the afternoon of December 17, 2025, the 2025 Brother Machine Tools Machining Application Sharing Seminar, jointly organized by Pro-Technic Machinery Group and Brother Machine Tools (Shanghai) Ltd., concluded successfully at the Brother Technology Center Ningbo.

The seminar precisely addressed the key challenges faced by emerging industries such as new energy automotive parts, robotics, and semiconductors, attracting numerous representatives from manufacturing enterprises to gather and explore cutting-edge technologies and practical solutions.

15 Dec

Review │ 2025 Brother Die Casting & Automotive Parts Technology Seminar (Nanjing) Successfully Held

On December 3, 2025, the Brother Die Casting & Automotive Parts Technology Seminar, jointly organized by Pro-Technic Machinery Group and Brother Industries of Japan, concluded successfully.

In response to the accelerating iteration of new energy vehicles and the rise of personalized consumer demand—bringing challenges such as increased component complexity, rising costs, and insufficient production line efficiency—this seminar aimed to provide practical smart manufacturing upgrade solutions for the automotive parts industry. The event supported enterprises in advancing toward a more efficient, lean, and sustainable production model.

5 Dec

Review │ 2025 Smart Manufacturing Technology Seminar & Solutions Exhibition Concludes Successfully

From November 26 to 28, 2025, the three-day Smart Manufacturing Technology Seminar & Solutions Exhibition successfully concluded at the Pro-Technic Complex Building in Chang’an Town, Dongguan.

From November 19 to 22, 2025, the annual manufacturing event of Southeast Asia—METALEX Thailand, held at the Bangkok International Trade & Exhibition Centre (BITEC)—was grandly opened.

At this highly anticipated industry exhibition, Pro-Technic Machinery Group made a powerful appearance, showcasing a range of cutting-edge technologies and products, presenting its latest achievements in high-efficiency machining and digital manufacturing.

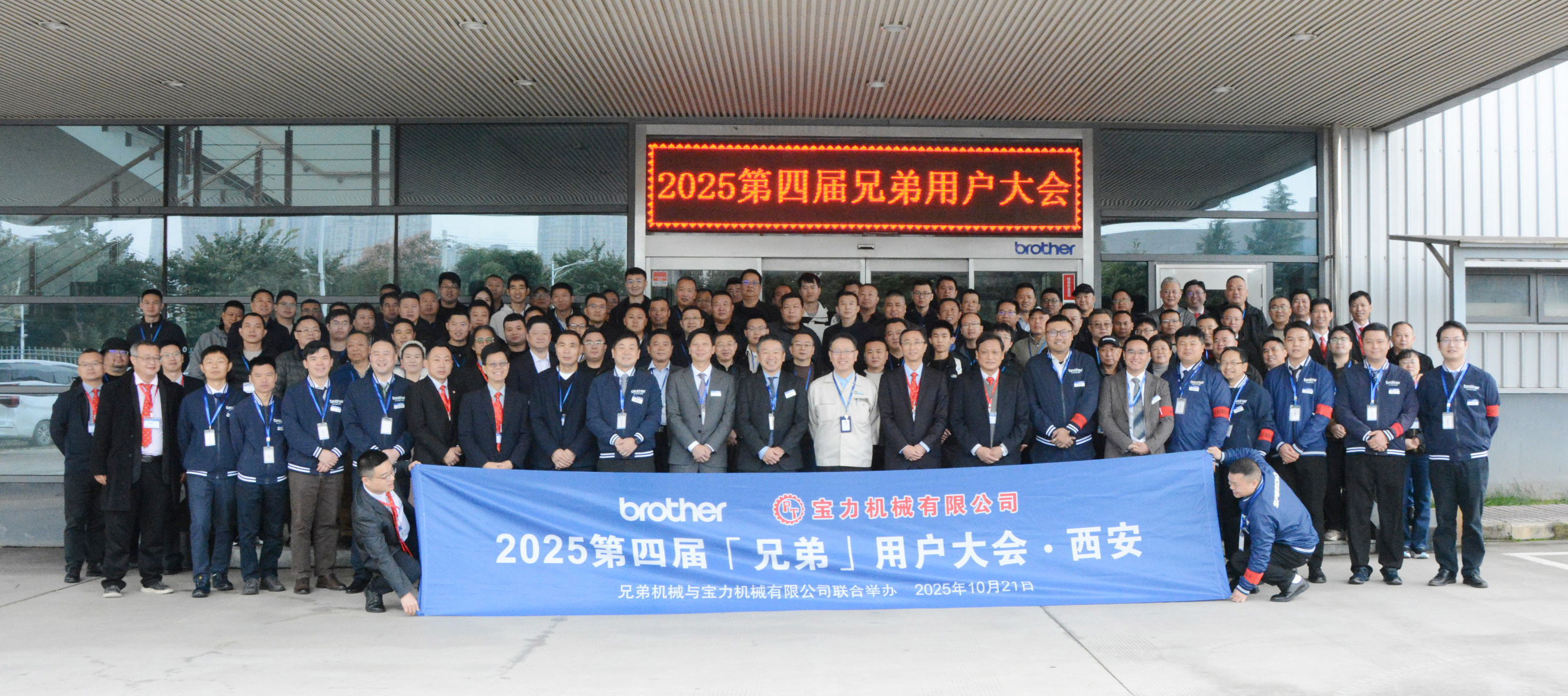

The 4th “BROTHER” User Conference Successfully Concluded on October 21, 2025. We extend our sincere appreciation to all guests for your enthusiastic participation, as well as to all staff members for their dedicated efforts. Looking ahead, Pro-Technic looks forward to working together with you to achieve new milestones on the journey toward intelligent manufacturing.

As the National Day and Mid-Autumn Festival holidays approach, and in accordance with the national holiday schedule combined with our company’s actual situation, the holiday arrangement of Pro-Technic Machinery Group is as follows:

Holiday Period:

October 1 (Wednesday) to October 6 (Monday), 2025 — 6 days off

Work Resumption:

October 7 (Tuesday), 2025 — Normal operations resume

All employees of Pro-Technic Machinery Group wish you a Happy National Day and Mid-Autumn Festival!

May our motherland continue to prosper and flourish, and may you and your family enjoy happiness, reunion, and good health.

Solution Centre

Solution Centre Service Hotline 400-889-8282

Service Hotline 400-889-8282