News

Pursuing High Rigidity, High Precision, and High Productivity — A Multi-Processing Machine for Large-Diameter Bar Workpieces

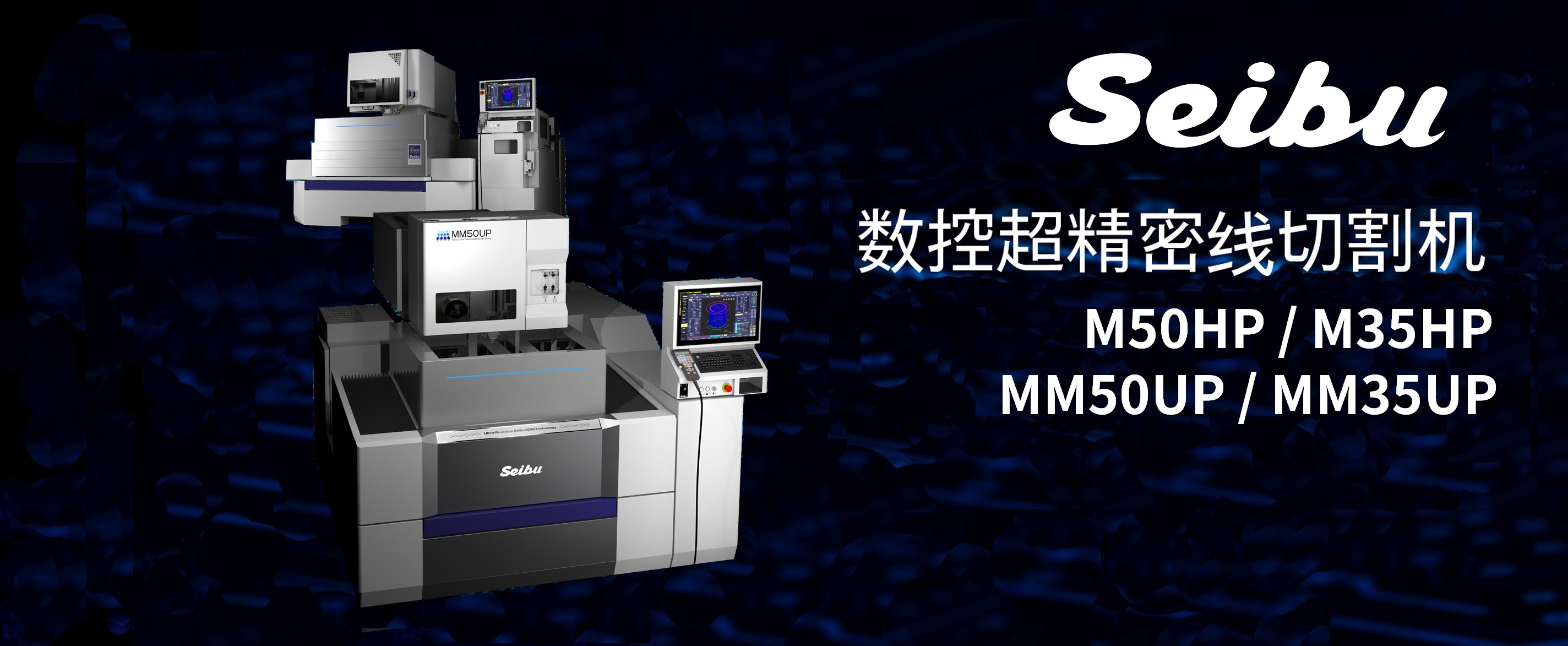

Seibu Electric successfully developed the world’s first CNC wire-cut EDM machine. Since then, the company has introduced a series of high-performance, high-precision wire EDM machines, making significant contributions to improving production efficiency. Building on this foundation, Seibu further developed ultra-precision wire EDM machines designed for mold processing in chip lead frames, motor cores, as well as electronic components and medical parts. By applying repeated “hand scraping” techniques, these machines achieve surface quality beyond the reach of conventional machining, delivering exceptional processing accuracy.

8 Aug

Brother Japan Best-Selling Series │ Made in Japan S300/S500/S700Xd2, Made in China S500/S700Zd2

In September 2024, Brother Japan launched the new generation Xd2 Series, developed to meet the requirements of integrated die-cast components in the EV industry. While maintaining a compact footprint, the Xd2 Series offers extended Y-axis and Z-axis travel, significantly expanding the machining range of workpieces.

To further enhance supply convenience, Brother also introduced local production of the Zd2 models in Xi’an, ensuring more efficient delivery channels for customers in the region.

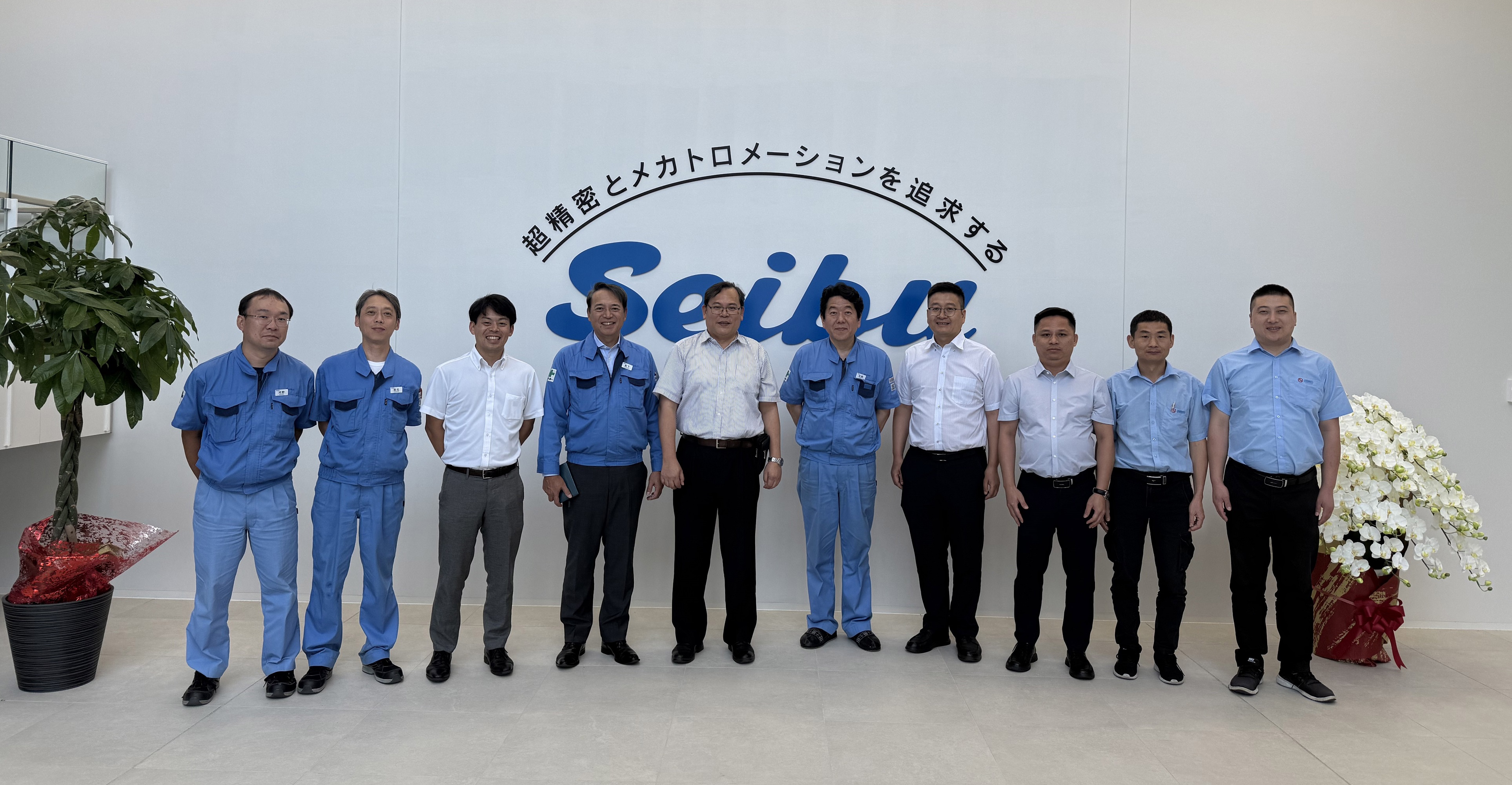

To deepen technical collaboration and enhance capabilities in high-end machine applications, the Pro-Technic Machinery technical team conducted a six-day dedicated technical exchange with Seibu Electric & Machinery Co., Ltd. in mid-July 2025. The program covered key activities including a new factory tour, advanced model training, discussions on delivery inspection standards, and hands-on testing — all yielding fruitful results.

On July 16, 2025, the “5-Axis Machining · Exploring Small-Batch Flexible Manufacturing” seminar, organized by Brother Machinery Commercial (Shanghai) Co., Ltd., was successfully held at the Brother Machinery Technology Center (Dongguan). Pro-Technic Machinery invited numerous corporate users and technical professionals to attend the seminar. The event focused on current manufacturing demands for small-batch, multi-variety, and high-precision production, with in-depth discussions on the application of 5-axis machining in flexible manufacturing. Live demonstrations, case studies, and interactive exchanges attracted a large number of participants and created a vibrant atmosphere.

The 20th Shanghai International Automotive Manufacturing Technology & Material Show (AMTS 2025), a three-day event, successfully concluded at the Shanghai New International Expo Center. As a major industry event in the automotive manufacturing field, the exhibition focused on traditional technologies such as body stamping and welding, as well as innovative applications in engineering, providing a highly valuable platform for exchange across the automotive and related sectors.

From July 2 to July 5, 2025, the 21st Vietnam International Machine Tools, Manufacturing, Metalworking, Hardware and Automation Exhibition (MTA VIETNAM 2025) was successfully held at the Saigon Exhibition & Convention Center (SECC) in Ho Chi Minh City. Bringing together leading global enterprises and cutting-edge manufacturing technologies, the exhibition once again served as a key platform for innovation and industry exchange.

At this major industry event, Pro-Technic Machinery Group made a strong impression with its outstanding presence, demonstrating not only its technical strength but also its long-term commitment and confidence in the future development of Vietnam’s machinery industry.

The 2025 Japan「Brother」Speedio D00 Series Pilgrimage events were successfully held in Tianjin, Chongqing, and Shanghai, allowing customers to review the latest models, including the popular S500/700Zd2, W1000Xd2, and the brand new M200Xd1, along with new features such as tool holder chip detection, gear cutting functionality, and no warm-up function.

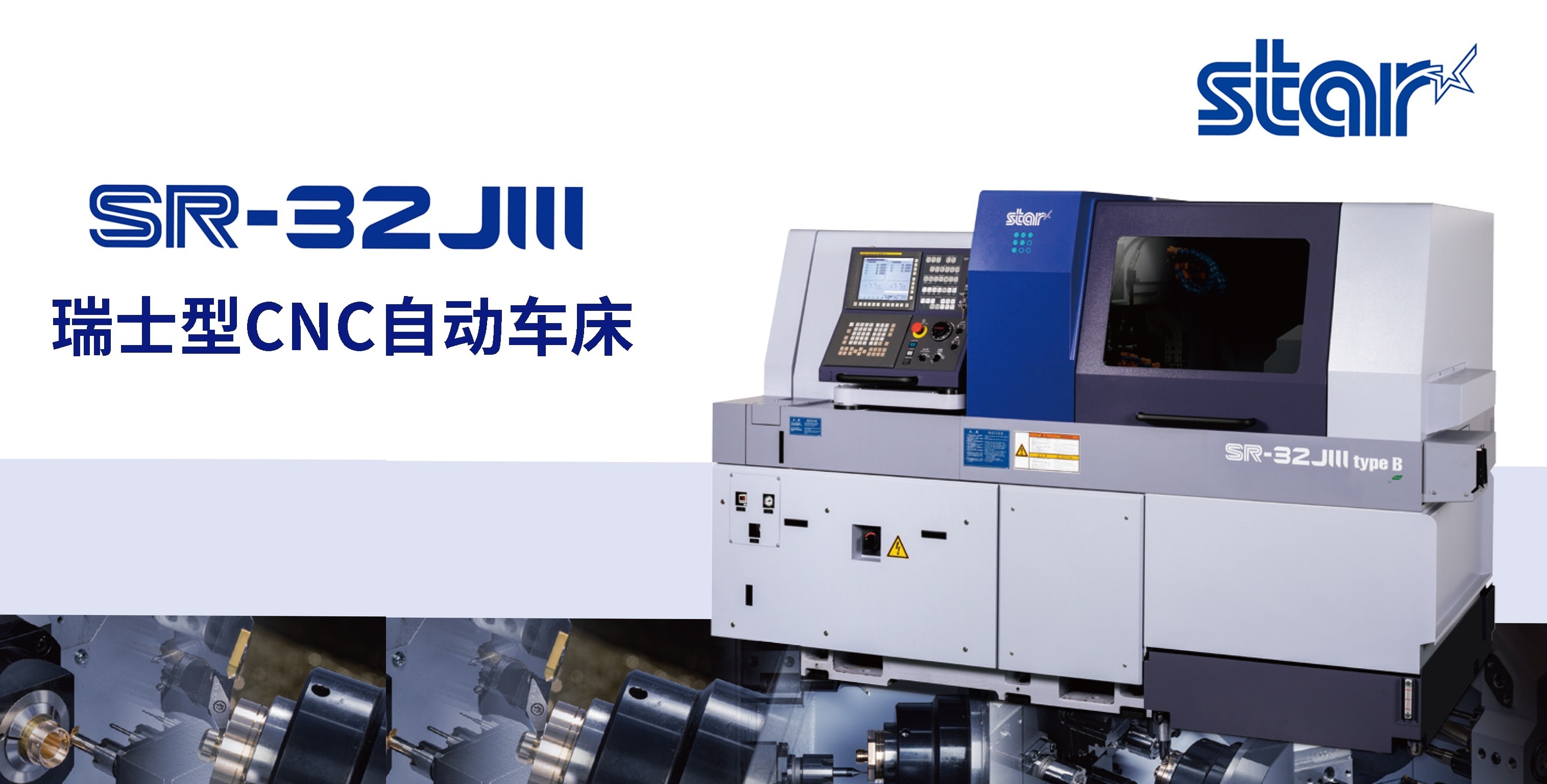

On June 18, 2025, the “2nd「STAR」User Conference” organized by Pro-Technic Machinery Ltd. and Shanghai Xingang Machinery Co., Ltd. successfully concluded at the Pro-Technic Integrated Building. This conference gathered industry elites, partners, and loyal users of the「STAR」series products to witness the「STAR」product line and cutting-edge technologies, discuss industry trends, and share practical processing cases.

Solution Centre

Solution Centre Service Hotline 400-889-8282

Service Hotline 400-889-8282