MK7 系列具 有多项革命性和突破性的设计。MK7系列结合客户需求 ,优化 Del ta T, 减少耗氮星, 延长保养间隔时间 。汇集各项优化功能的同时降低了机身高度 ,使视野更开卤 。 He lle「欢迎您参观我们的研发中心和制造工厂,亲自在 MK7 的设备上做 PROFILE 测试 ,共同见证 M K7系列的强大功能及优势。或者将您的产品寄给我们,我们会将 PROFILE 的 测试结果与您分享 。 He ller很高兴为您提供订制化的产品满足您特殊的 制成需求 。

■New Low Height T叩 Shell 最新低顶盖设计

New low height top shell p「ovides much easier access for operators.All skins have double insulation to save up to 10-15% in energy costs MK7采用最新低顶盖设计,方便客户的操作和保养 ,机器的表面温度更低 ,环保节能 。

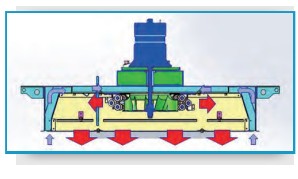

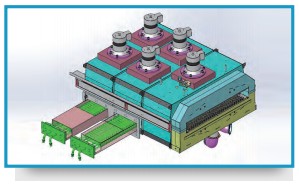

■Enhan cedLow Height Heater Modules 优化的新型加热模组

Enhanced low height heate 「 moduleprovides thelowest Delta Ts on the p「 oductwith belle 「 air flow and uniformity! The Uniform Gas Management system eliminates」net flow」 which「esultsinn市ogenconsumption

「eductionsof up ta4□%! New semi-「cicularheater ismore robust and efficient with much long「e lifetime

优化的低高度加热模组,实现最佳均温性,

最高可减少氮气消耗 40%,均衡气流节省氮气 。新型加热丝加热效率更高 ,寿命更长。

■Revalutianary Flux Management System 革新的助焊剂回收系统最少维护时间,最多生产时间,最高产量!

Our「evoluiton「ay flux collection system traps the flux in collection ja「 s that can be easily removed and replacedwhile the aven is running—savingtime consuming P.M. The new flux filtration box also has no risk of flux clogging fo「 a longer te「m P.M. interval. Add小onally,our prop「ietary Flux-Free Grill system limits the flux 伦 sidue on the cooling g「iIls giving the Helle「 systemthe highestp「oduclion yields of any ovenl

革新的助焊剂回收系统用收集瓶回收助焊剂易更换清理; 可实现在线保养维护,延长保 养周期,缩短保养所需时间 , 特殊冷却区设计,冷却区层板无助焊剂残留 。

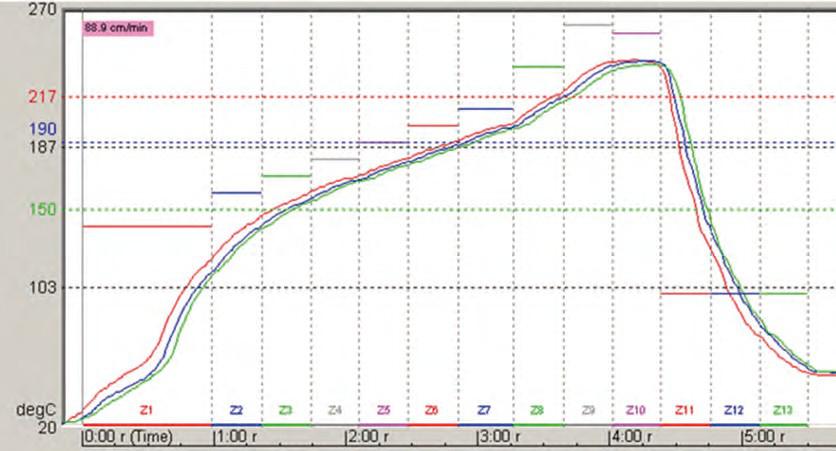

■Programmable Cooling 极富灵活性的下降斜率

The new Big Flat Coil Cooling modulep「ovidescoo「l ates of >3°C/sec. That rate meets even the most demanding lead-free p「ofile「equ「i ements.Helle「 canalso easily achieve slow cooling rate「equ「i edby theflip chip process. Heller’sunique design using a 10-ni ch (250 mm) long hea「temodule p「ovidesmore modules within the same heating lengthwhich means mo「ep「ocesscontrol and「educedliquid times

最新平板式冷却模组,能满足最严苛的 温度曲线要求 ,可达到 3度/秒以上的下降斜率 ,亦可轻松应对缓慢下降要求,独特的 10英寸加热模组 ,拥有业内相同加热长度下最多温区 ,最多温控点 。

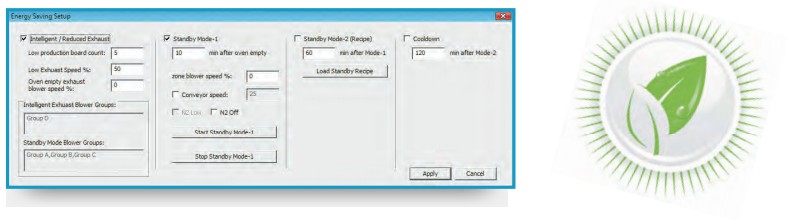

■Energy Management Software 能源管理软件

竹oprietarsyoftw「a e allows you to p「ogramexhaust draw to optimize en「egyconsumption during the various p「oductiontimes – heav,ylighto「 idle Energy savings of up to 1D-2D% have been realized!

HELLER专 有能源管理软件,智能化管理能源消耗 ;依据生产状 态(满载 少呈或闲置),自动调整设备抽排风 。实现能 耗节省高达IDH20%!

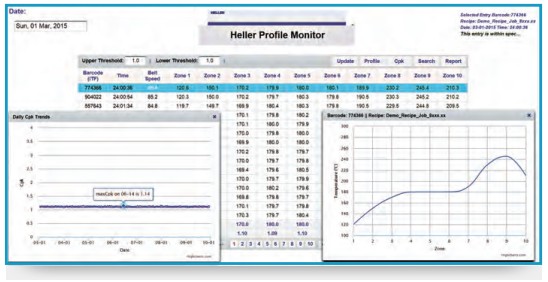

■Reflow □venCPK 回流炉 CPK-实时监控工艺参数 ,有效提升产能和品质!

Hell「e p「ovidesdynamic 3 tiered system (Tier1: Oven CPK, Tie「 2P「ocessCPK, T旧 3P「oduct Traceability) enables custom「e to quickly imp「ovep「oductquailty and yield while「educingcosts. And the add小onal benefits of automati「c eco「d keeping and「ecall p「ovide custom「es with the peace of mindthat all p「ocess parameters a「e under control and withinspec

三阶数据 管 理

第一阶· 回流炉 CPK

第 二 阶 工 艺 CPK

第三阶产品追溯性管理