Vertical Curing Dven

垂直烘烤炉

Heller has developed Vertical Curing Ovens for inline applications.By the design of vertical transfer,it is able to save costly floor space and get stable temperature prolfiles.

Compared with traditional ovens,vertical curing oven can fulfill the automatic in line production with superior temperature uniformity.Major applications:Die Atach,Flip Chip,Underfill,COB Encapsulation.

Heller开发的垂直炉可取代原有的普通烤箱,实现自动化在线烘烤制程;通过特殊的垂直方向传输,可大幅减少占地面积,获得稳定的温度曲线;克服了传统烤箱无法进行自动化生产的缺点,且均温性明显优于传统烤箱;垂直烘烤炉的主要应用包括:芯片贴装,倒装,填胶,COB封装等。

Features主要特点

·Small Footprint-as small as 185cm占地面积小,总长度仅有185cm

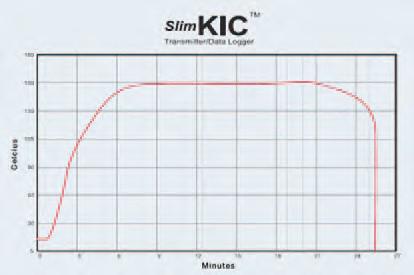

·Fast Curing Time-down to 7.5 minutes可用于快速烘烤,最短烘烤时间仅为7.5分钟

·Adjustable Curing Times-up to several hours烘烤时间可调,最短几分钟,最长几个小时

·Adjustable Product Width-from 7.5cm to 35cm产品宽度可调,最小7.5厘米,最大35厘米

·Air Atmosphere(nitrogen optional)

空气炉

·SMEMA Compatible兼容SMEMA标准

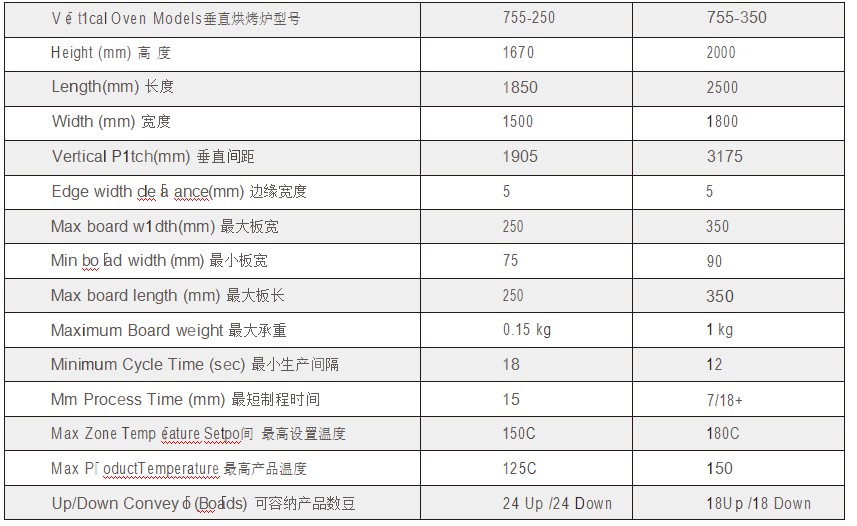

Heller Vertical Oven Specifications

Heller垂直烘烤炉型号与规格

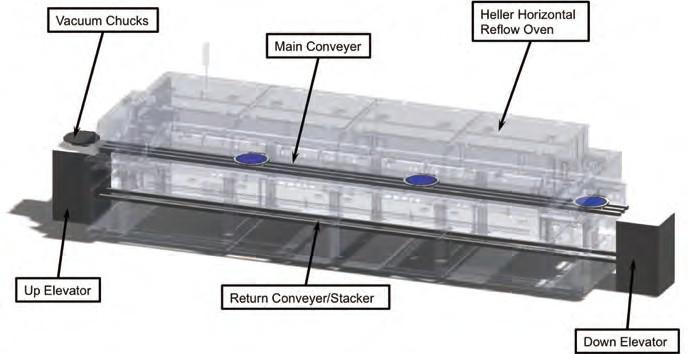

Vacuum Clamp Conveyar

真空夹具

Heller Industries has invented a vacuum clamp that moves within a conveyor belt system inside a horizontal reflow oven.Vacuum clamp carriers return underneath oven from exit to entrance to provide continuous operation.This vacuum clamping design has proved effective for wafer or substrate warpage mitigation.

Heller 开发的真空夹具系统,是和配置真空轨道的回流焊设备一体化的整套系统。真空夹具从炉膛入口处到出口处循环运转,自动回收,实现在线式生产。无论是晶圆回流还是基板回流,这套真空夹具都可有效解决产品的板弯板翘问题。